【Remark】:

ROHS directive has publicized. During the welding process with lead-free, all of the electron manufacturers are thinking one question how to ensure the quality of lead-free welding.It is all known that the lead-free welding is more difficult than lead welding in welding technic and quality control.In the century with lead-free,Torch applies itself to search the way how to satisfy the product with the trial-manufacture of lead-free welding and the manufacture of small batch and high quality for many years.

According to the practical requirement of small and middle sized electron factory, the small batch trial- product in research center .T200C is designed and manufactured by Torch technologists on the basis of technical accumulation for many years. It has many specialties such as high precision, multi-function; practicality; steady capability; long life; energy-saving with high efficiency; viewable operation. It adapts to the research and production in research center, war industry, middle and small-sized corporation, small Private Corporation and other electronic production companies

Unique features :

▲ High precision ,multi- functions

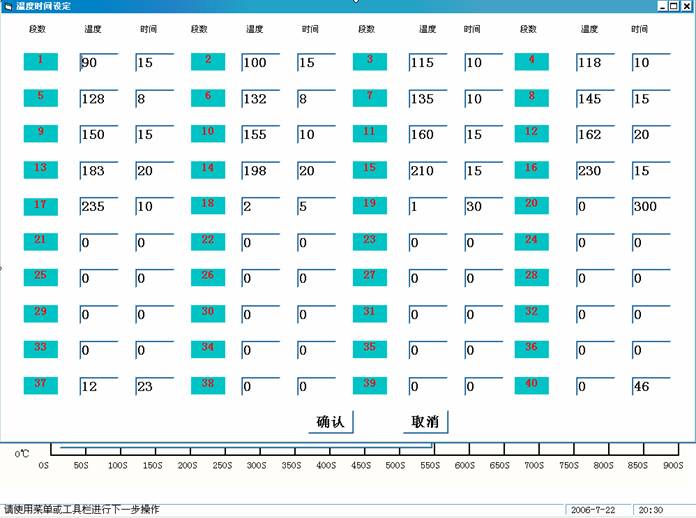

40 segment temperature curves can be set. It satisfies the welding of different component.

▲ Computer control

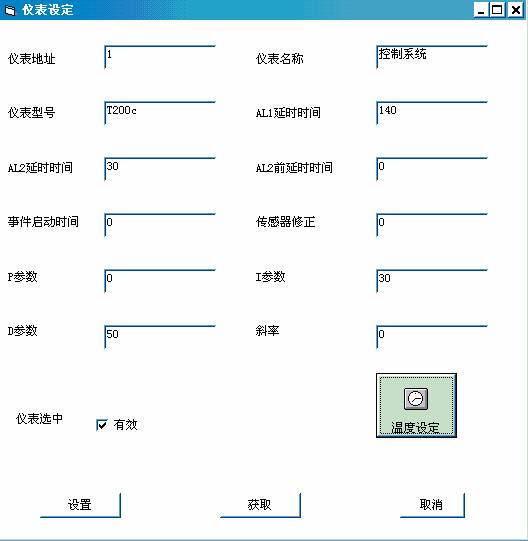

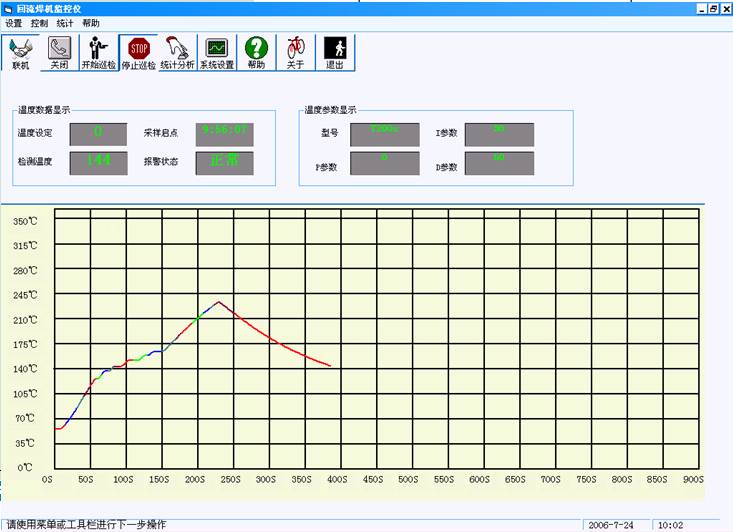

T200C breaks through the shortages such as the difficulty of meter control program, the difficulty of modify parameter, limited storage of temperature curve. It adopts the software for temperature control, which is produced by Torch itself. The temperature curve can be set intuitively. And a large number of temperature curves can be stored. Analysis and statistics function, printing function.

Batch setting of 40 segment temperature curve

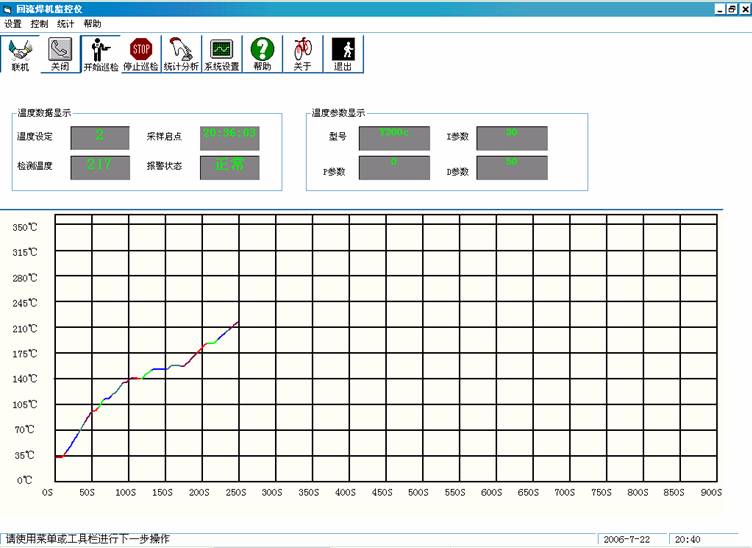

Temperature curve that being tested

Tested temperature curve

Real time testing with temperature curve

Test the temperature curve of soldering at every time. During the process of welding, the actual temperature can be displayed at the same time. It is convenient to adjust and control the lead-free curve. Especially control the heat preservation zone and the melting zone

▲ Viewable operation, The real time display of temperature and the real time observation of the welding process. It is the best choice for science research and teaching.

Technical instruction

A: Temperature control segment: 40 segment

The segment can be set in computer according to the actual requirement.

B: Temperature-zone numbers : Single-zone and multi-segment

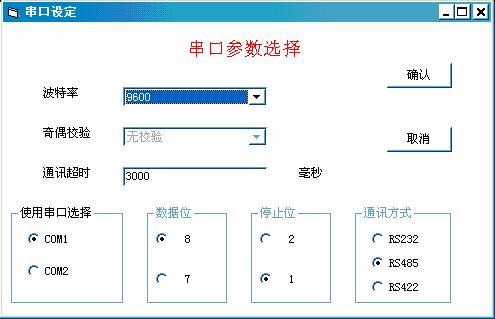

C: Temperature control system:PC control system ,SSR non-contact output

D: Temperature accuracy : ± 2 ℃

E: Warm-up time: 3min

F: Temperature range :Room-temperature -360 ℃

G: Heating supply :Infrared ray + Hot air convection

H: Effective working table area:360mm * 230mm (less than A4)

I: Welding time : 3min ± 1min

J Temperature curve: It can be set ,adjusted and tested according to the actual requirement .

K: Cooling system:Transverse flow equal cooling

N: Rated voltage: AC single-phase, 220V; 50Hz

O: Rated power : 3.8KW Mean power: 1.6kw

P: Weight: 39 kg

Q: Dimension :Length*width*height 700 ′ 460 ′ 310mm

|